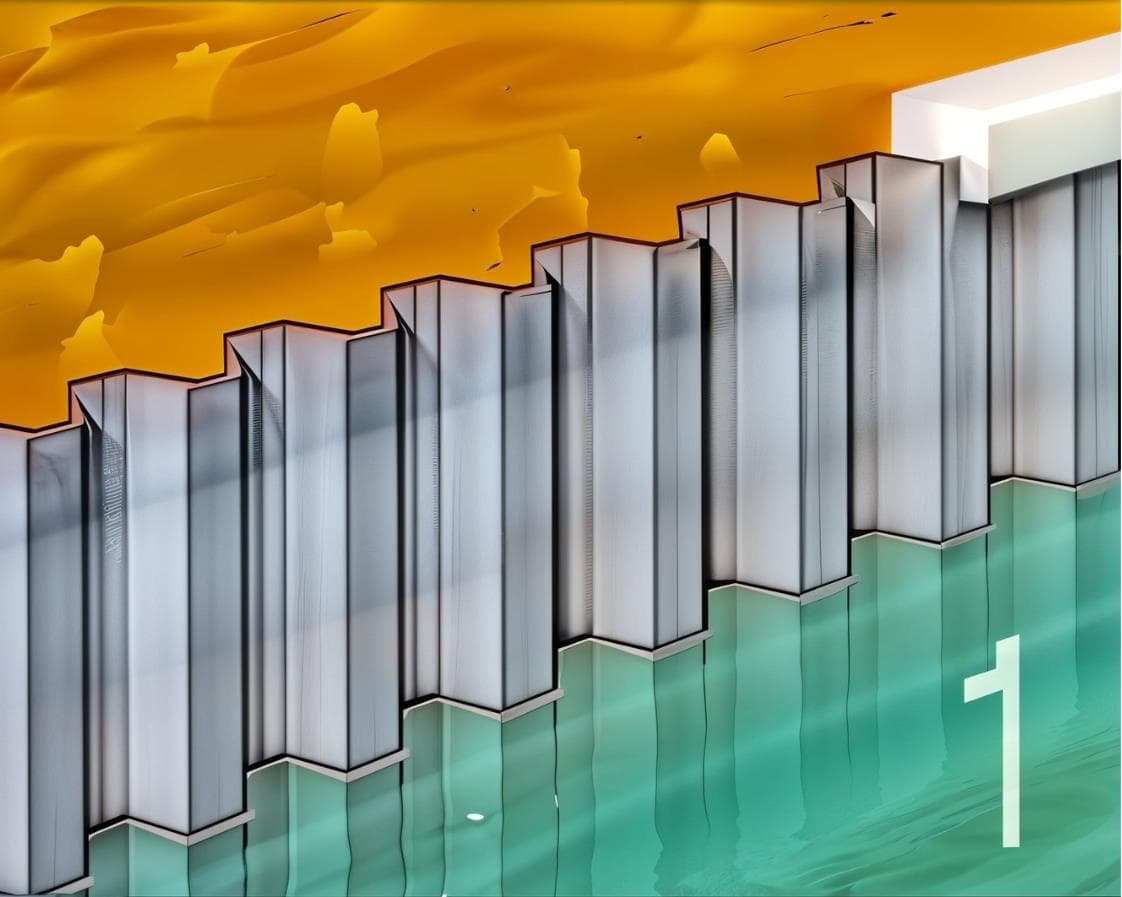

Capping Formwork System

Faster, More Cost-Effective Sheet Pile Capping with the Dawson Formwork System

The Dawson capping formwork system is the only purpose-built solution for concrete cap formwork—delivering speed, efficiency, and cost savings over traditional on-site setups. Unlike makeshift ‘lash-ups,’ it eliminates welding, cutting, and excessive labour, making it the smarter choice for any project.

Why Choose Dawson Formwork?

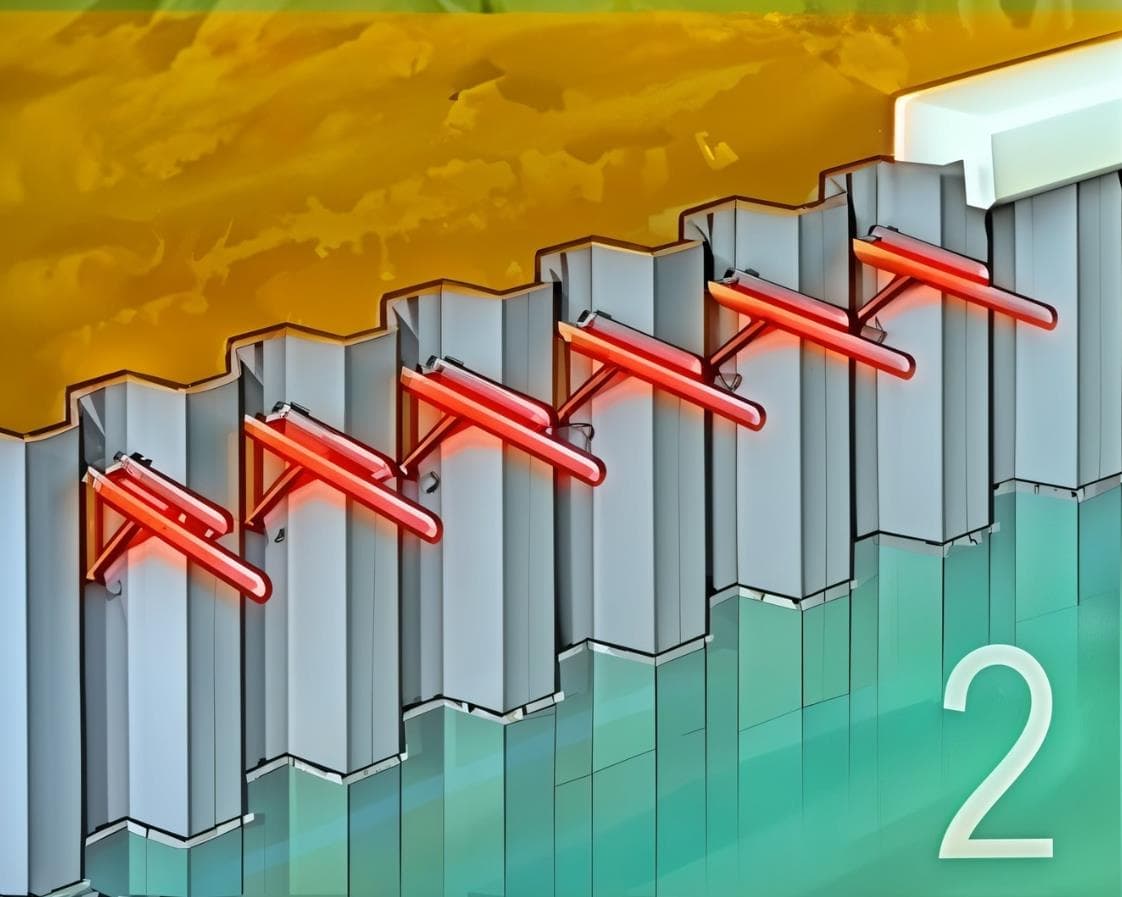

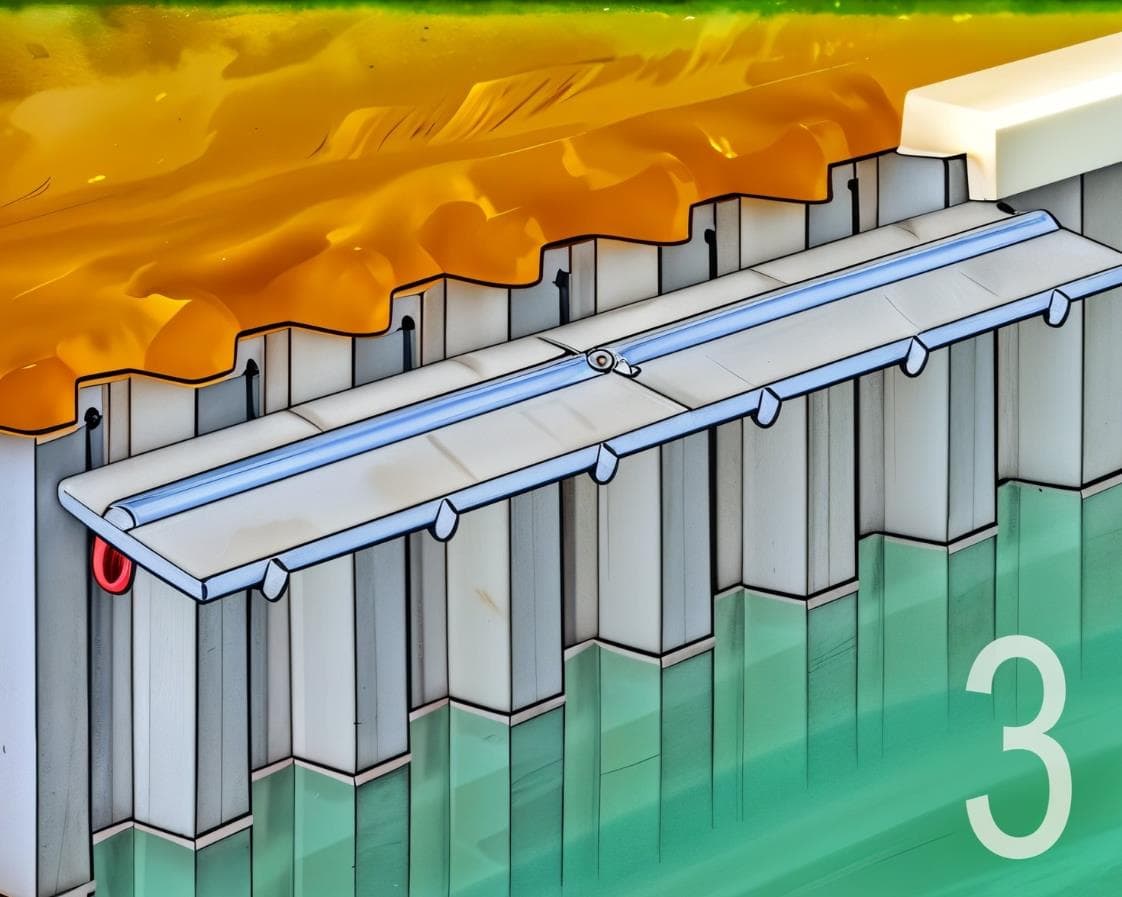

- Saves Time & Labour Costs – Easily assembled and re-used by unskilled labor, with no need for welding or cutting.

- Eliminates Waste & Hassle – No more individually cut plywood formwork or welded brackets that must be burned off later.

- Proven Performance – A 275m concrete cap (1.2m high x 0.9m wide) was completed in just four weeks, with 15m pours completed daily using 45 Redeb brackets and 18 soffit panels.

Designed for Strength & Versatility

- Supports soffit shuttering for U- and Z-shaped sheet piles.

- Durable yet lightweight brackets designed for years of trouble-free service.

- Three bracket models (RSB500, RSB600, and RSB700) to fit a wide range of sheet pile sections.

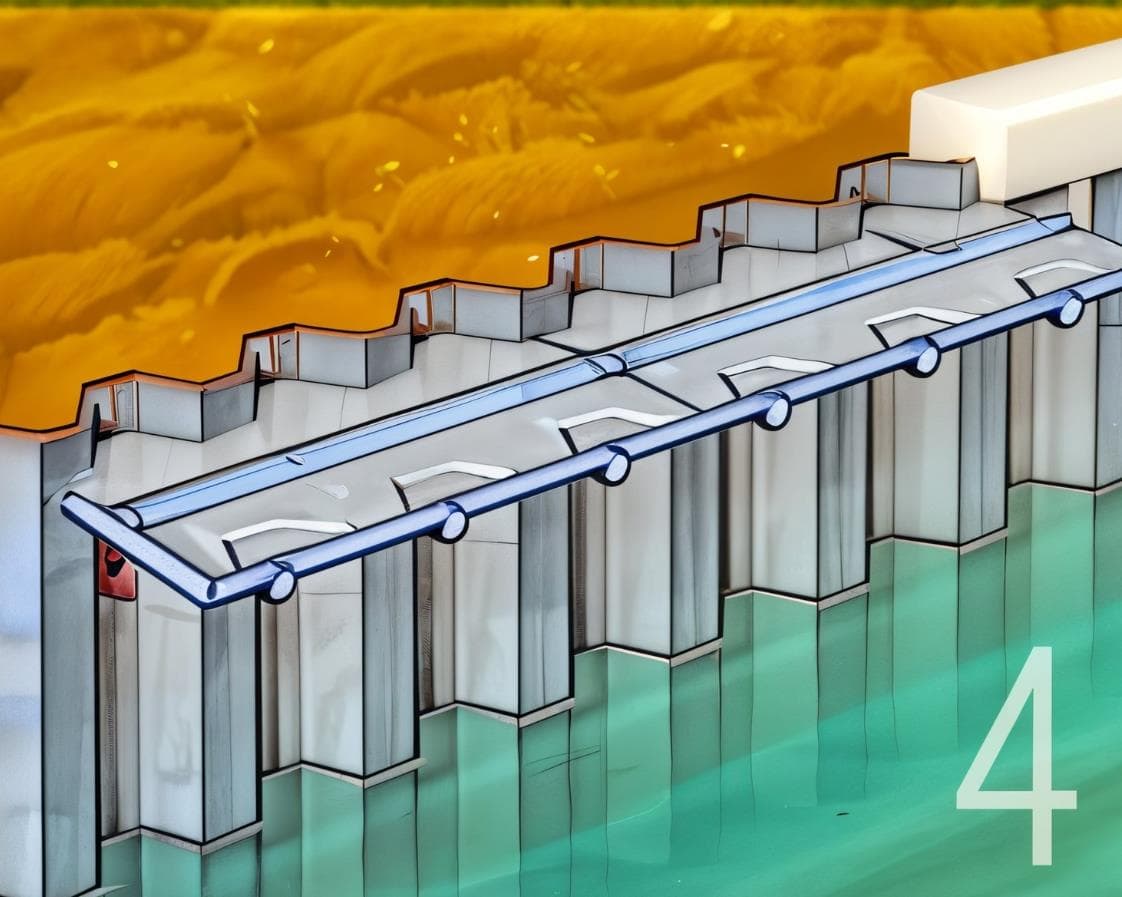

- Two soffit panel sizes (2.5m and 3m), designed for mechanical handling.

- Supports Combi-walls.

More Than Just Aesthetic Appeal

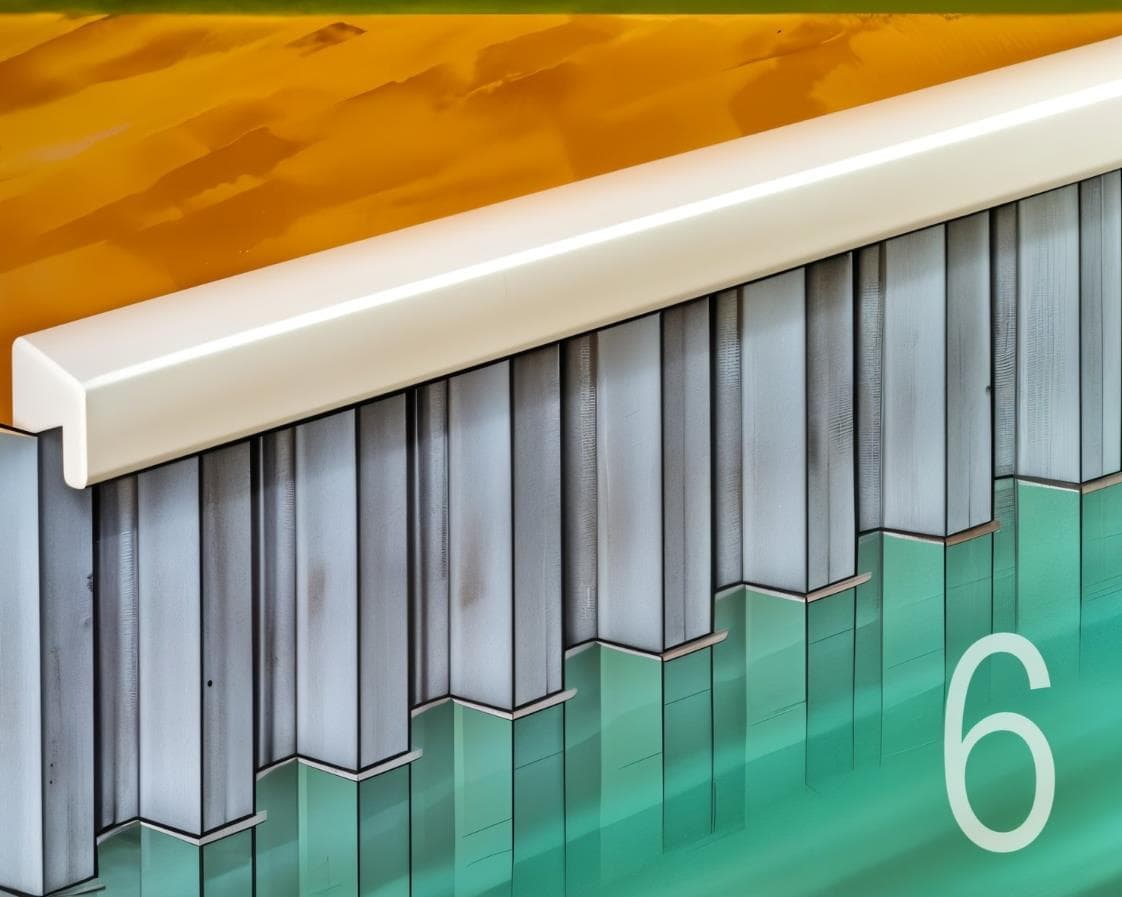

Concrete capping isn’t just about looks—it conceals irregularities in pile length, depth, and alignment while also serving as a base for railings or safety barriers.

The Dawson system is engineered to maximize efficiency and minimize complications, making it the go-to choice for contractors looking to streamline sheet pile capping.

For a faster, simpler, and more cost-effective solution, choose Dawson.

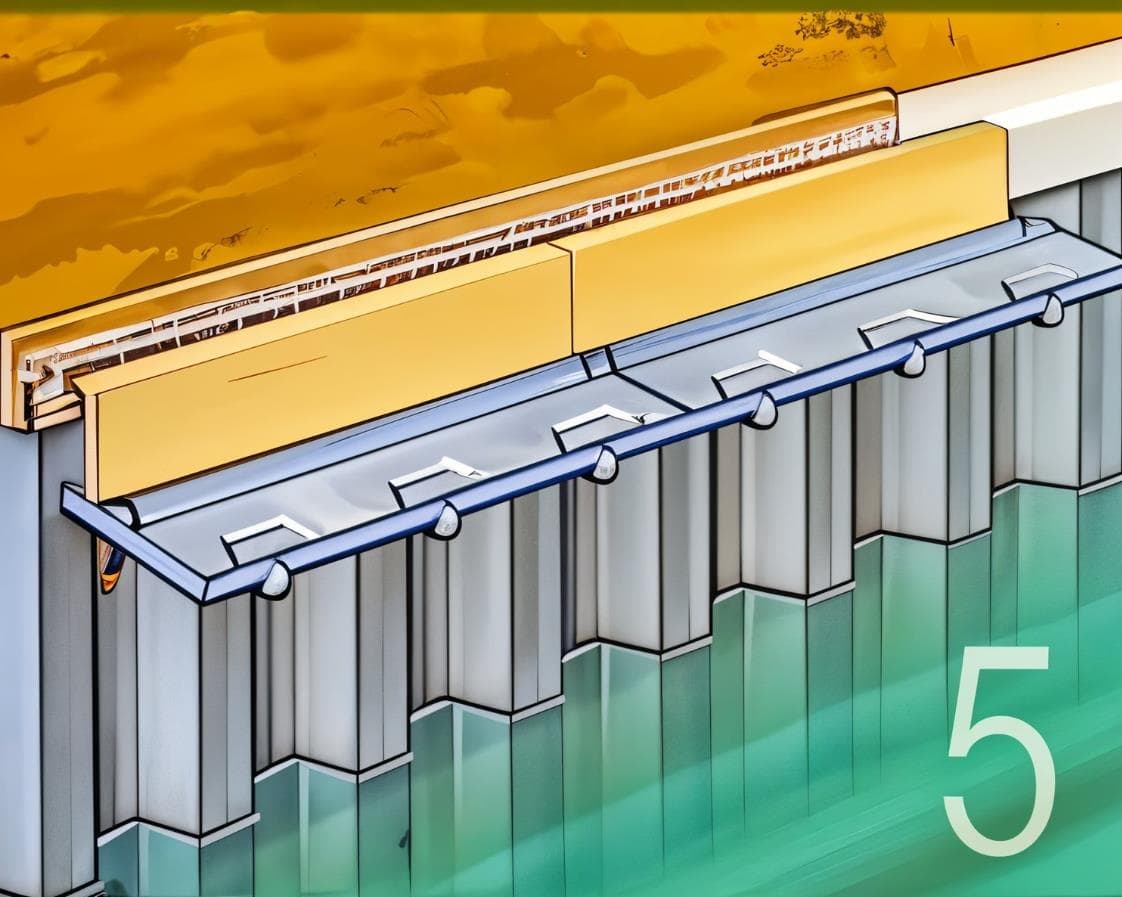

Step-by-step assembly of brackets & panels:

For a quotation, please ensure you provide the following:

- Size of the Cap – Height & Width.

- Any overhang.

- The Sheet Pile Profile.

- Site Plan in the form of a drawing (this is not compulsory but advisable).